How to make hovercraft skirt

How To Make Hovercraft Skirt. Punch holes on the inside of the skirt in the middle of the flap on the top and the bottom of the skirt with the grommet kit. The skirt is most important part of hovercraft as it creates a cushion of air which lifts hovercraft and eliminates contact frictions. Refer image 1 and 2. Obtain a quantity of non steel belted tires of the same size from a recycling yard and cut the sidewalls off.

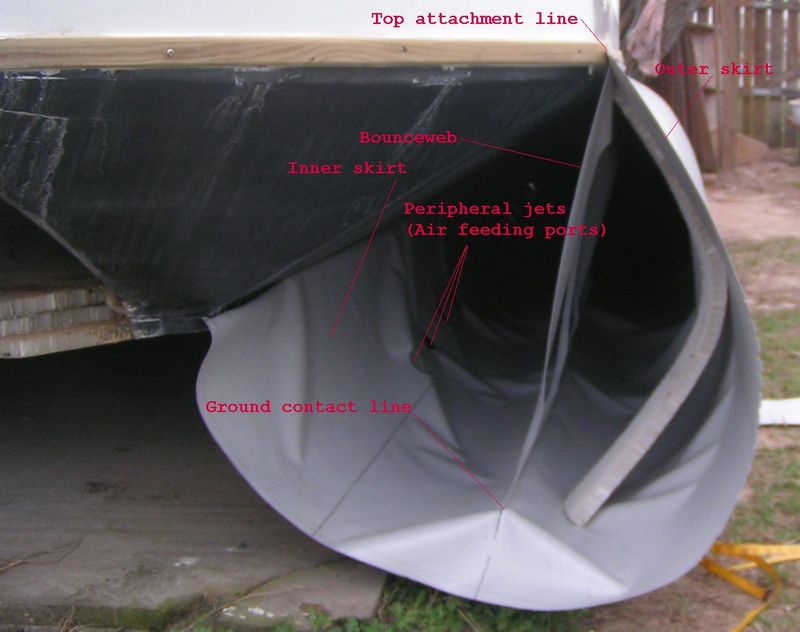

Hovercraft Bag And Finger Skirt Provided By 4 Wings Hovercraft Development From 4wings.com.phtemp.com

Hovercraft Bag And Finger Skirt Provided By 4 Wings Hovercraft Development From 4wings.com.phtemp.com

This is best suited to light racing hovercraft due to its low co efficient of drag. Leave about 2 inches of sidewall on each side of the thread to make an attachment lip or flange on the hovercraft. Punch holes on the inside of the skirt in the middle of the flap on the top and the bottom of the skirt with the grommet kit. This one directs approximately 1 3 of the thrust air to provide both lift and inflating the skirt. Refer image 1 and 2. Most of the materials could be found at the local builders supply.

Cut also the innermost outline of your hovercraft and discard the small shape so you have a doughnut shape which matches the base of your hovercraft.

These notes are for a skirt having all four corners identical as in the griffon 2000 range of. The only parts we needed to buy from universal hovercraft were the plans propeller propeller hub and the skirt material. Design also requires the use of an air chamber to evenly distribute the air into each finger section. Most of the materials could be found at the local builders supply. Cut also the innermost outline of your hovercraft and discard the small shape so you have a doughnut shape which matches the base of your hovercraft. This one directs approximately 1 3 of the thrust air to provide both lift and inflating the skirt.

Source: id.pinterest.com

Source: id.pinterest.com

This design is more complex than the bag skirt. Most of the materials could be found at the local builders supply. This one directs approximately 1 3 of the thrust air to provide both lift and inflating the skirt. Quite often the first model hovercraft a modeller builds leads to disappointing operation. Make sure the outer edge of the skirt fits the model.

Source: youtube.com

Source: youtube.com

Punch holes on the inside of the skirt in the middle of the flap on the top and the bottom of the skirt with the grommet kit. Design also requires the use of an air chamber to evenly distribute the air into each finger section. The only parts we needed to buy from universal hovercraft were the plans propeller propeller hub and the skirt material. Firstly place that body which you have cut in the last step and place it on the plastic sheet take the offset of around 1 1 5cm and cut off extra plastic. Most hovercraft use a separate motor for lift and thrust.

Source: pinterest.com

Source: pinterest.com

Cut also the innermost outline of your hovercraft and discard the small shape so you have a doughnut shape which matches the base of your hovercraft. Best suited to multi terrain cruising hovercraft. These notes are for a skirt having all four corners identical as in the griffon 2000 range of. This design is more complex than the bag skirt. Most of the materials could be found at the local builders supply.

Source: 4wings.com.phtemp.com

Source: 4wings.com.phtemp.com

The only parts we needed to buy from universal hovercraft were the plans propeller propeller hub and the skirt material. Cut also the innermost outline of your hovercraft and discard the small shape so you have a doughnut shape which matches the base of your hovercraft. Obtain a quantity of non steel belted tires of the same size from a recycling yard and cut the sidewalls off. Place the vehicle over the centre hole on your skirt pattern and fold the left and right sides up then the front and back edges. Put holes on all corners and every foot along the length of each side.

Source: 4wings.com.phtemp.com

Source: 4wings.com.phtemp.com

Place the vehicle over the centre hole on your skirt pattern and fold the left and right sides up then the front and back edges. Most of the materials could be found at the local builders supply. These notes will lead the reader through the stages needed to make a skirt segment pattern to make a skirt that will enable their model to show its true potential. Refer image 1 and 2. Leave about 2 inches of sidewall on each side of the thread to make an attachment lip or flange on the hovercraft.

Source: 4wings.com.phtemp.com

Source: 4wings.com.phtemp.com

Most hovercraft use a separate motor for lift and thrust. Put holes on all corners and every foot along the length of each side. Design also requires the use of an air chamber to evenly distribute the air into each finger section. Quite often the first model hovercraft a modeller builds leads to disappointing operation. Cut also the innermost outline of your hovercraft and discard the small shape so you have a doughnut shape which matches the base of your hovercraft.

Source: instructables.com

Source: instructables.com

Most hovercraft use a separate motor for lift and thrust. The only parts we needed to buy from universal hovercraft were the plans propeller propeller hub and the skirt material. The skirt is most important part of hovercraft as it creates a cushion of air which lifts hovercraft and eliminates contact frictions. This is best suited to light racing hovercraft due to its low co efficient of drag. Place the vehicle over the centre hole on your skirt pattern and fold the left and right sides up then the front and back edges.

Source: pinterest.com

Source: pinterest.com

The skirt is most important part of hovercraft as it creates a cushion of air which lifts hovercraft and eliminates contact frictions. Best suited to multi terrain cruising hovercraft. Quite often the first model hovercraft a modeller builds leads to disappointing operation. Obtain a quantity of non steel belted tires of the same size from a recycling yard and cut the sidewalls off. Most hovercraft use a separate motor for lift and thrust.

Source: youtube.com

Source: youtube.com

Old tires have thick rubber and can be used effectively to make a skirt. Cut also the innermost outline of your hovercraft and discard the small shape so you have a doughnut shape which matches the base of your hovercraft. Refer image 1 and 2. Firstly place that body which you have cut in the last step and place it on the plastic sheet take the offset of around 1 1 5cm and cut off extra plastic. Design also requires the use of an air chamber to evenly distribute the air into each finger section.

Source: youtube.com

Source: youtube.com

Punch holes on the inside of the skirt in the middle of the flap on the top and the bottom of the skirt with the grommet kit. Make sure the outer edge of the skirt fits the model. This one directs approximately 1 3 of the thrust air to provide both lift and inflating the skirt. Drill holes through the base that line up with the grommets. Best suited to multi terrain cruising hovercraft.

Source: astounding.org.uk

Source: astounding.org.uk

Make sure the outer edge of the skirt fits the model. Drill holes through the base that line up with the grommets. This one directs approximately 1 3 of the thrust air to provide both lift and inflating the skirt. Refer image 1 and 2. Firstly place that body which you have cut in the last step and place it on the plastic sheet take the offset of around 1 1 5cm and cut off extra plastic.

Source: frenchesgrove.org

Source: frenchesgrove.org

Design also requires the use of an air chamber to evenly distribute the air into each finger section. This one directs approximately 1 3 of the thrust air to provide both lift and inflating the skirt. Refer image 1 and 2. Firstly place that body which you have cut in the last step and place it on the plastic sheet take the offset of around 1 1 5cm and cut off extra plastic. Drill holes through the base that line up with the grommets.

Source: pinterest.ca

Source: pinterest.ca

Obtain a quantity of non steel belted tires of the same size from a recycling yard and cut the sidewalls off. Refer image 1 and 2. These notes are for a skirt having all four corners identical as in the griffon 2000 range of. Firstly place that body which you have cut in the last step and place it on the plastic sheet take the offset of around 1 1 5cm and cut off extra plastic. Best suited to multi terrain cruising hovercraft.

Source: waynesthisandthat.com

Source: waynesthisandthat.com

Old tires have thick rubber and can be used effectively to make a skirt. Put holes on all corners and every foot along the length of each side. Most of the materials could be found at the local builders supply. This is best suited to light racing hovercraft due to its low co efficient of drag. These notes are for a skirt having all four corners identical as in the griffon 2000 range of.

Source: pinterest.co.uk

Source: pinterest.co.uk

Old tires have thick rubber and can be used effectively to make a skirt. Obtain a quantity of non steel belted tires of the same size from a recycling yard and cut the sidewalls off. Place the vehicle over the centre hole on your skirt pattern and fold the left and right sides up then the front and back edges. Drill holes through the base that line up with the grommets. Make sure the outer edge of the skirt fits the model.

If you find this site adventageous, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title how to make hovercraft skirt by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.