Iron malleability and ductility

Iron Malleability And Ductility. It s also highly malleable and with a lower melting temperature of 660 c allowing it to be easily manipulated 6. When a piece of hot iron is hammered it takes the shape of a sheet. The malleability of the same metals are then ranked from greatest to least. However in most cases ductility and malleability are coexisting.

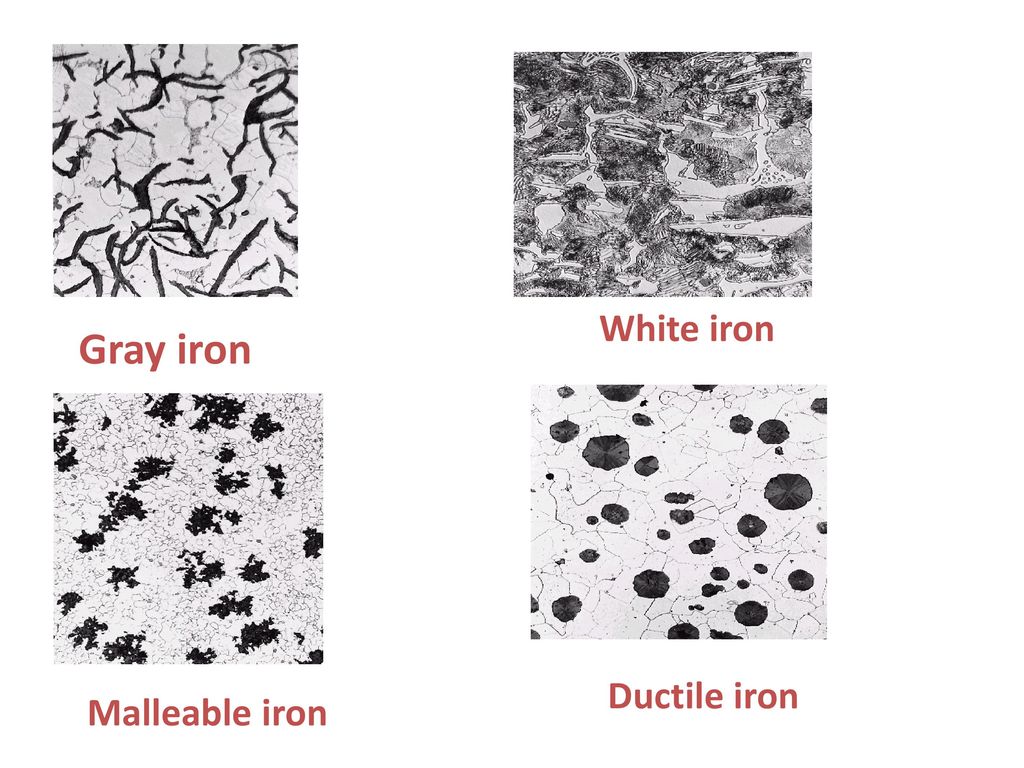

Malleable Vs Ductile Iron A Comparison Of Malleable And Ductile Iron From pvcfittingsonline.com

Malleable Vs Ductile Iron A Comparison Of Malleable And Ductile Iron From pvcfittingsonline.com

For example lead and cast iron are highly malleable though they have a lower ductility. When a piece of hot iron is hammered it takes the shape of a sheet. Gold silver lead copper aluminium tin platinum zinc iron and nickel. Malleability denotes the ability to undergo compressive stress. Increasing levels of carbon decreases ductility. Example are gold and silver which are highly malleable.

But in some cases ductility is high while malleability is low or vice versa.

Ductility is the ability of a metal to undergo tensile stress. Gold silver lead copper aluminium tin platinum zinc iron and nickel. The property is not seen in non metals. After doing the research and reading the facts we have concluded that while malleable iron is capable of great things ductile iron is the superior alloy. The most ductile metals are copper aluminum and platinum while the most malleable metals are gold silver and iron. 1 the ductility of steel varies depending on the alloying constituents.

Source: m.youtube.com

Source: m.youtube.com

It s also highly malleable and with a lower melting temperature of 660 c allowing it to be easily manipulated 6. The malleability of the same metals are then ranked from greatest to least. However in most cases ductility and malleability are coexisting. Gold silver lead copper aluminium tin platinum zinc iron and nickel. Aluminium is an incredibly ductile material able to be stretched between 50 to 70 of its length before breaking.

Source: differencebetween.com

Source: differencebetween.com

Sodium potassium and mercury are neither ductile nor malleable however nickel is a nonmalleable metal too. Ductility is the ability of a metal to undergo tensile stress. Ductility and malleability are properties related to deformation of metals. Lack of ductility is brittleness to understand brittleness lets also take a another mettalic bar this metallic bar when subjected to to axial tensile load we notice that bar does not elongate and fail so brittleness of a material is the property of breaking without much permanent distortion some brittle materials are glass cast iron etc. After doing the research and reading the facts we have concluded that while malleable iron is capable of great things ductile iron is the superior alloy.

Source: metalworkinginfo.blogspot.com

Source: metalworkinginfo.blogspot.com

Ductility is the ability of a metal to undergo tensile stress. This makes cracking a possibility. As with iron and aluminium copper is an abundant element on earth with large concentrations found in its crust. Lack of ductility is brittleness to understand brittleness lets also take a another mettalic bar this metallic bar when subjected to to axial tensile load we notice that bar does not elongate and fail so brittleness of a material is the property of breaking without much permanent distortion some brittle materials are glass cast iron etc. Example are gold and silver which are highly malleable.

Source: pediaa.com

Source: pediaa.com

This is the main difference between ductility and malleability. In more simple words ductility means stretching to wires and malleability means beating to sheets ductility means that a metal can be changed to another form by pulling compression or twisting. Aluminium is an incredibly ductile material able to be stretched between 50 to 70 of its length before breaking. Increasing levels of carbon decreases ductility. Malleability denotes the ability to undergo compressive stress.

In more simple words ductility means stretching to wires and malleability means beating to sheets ductility means that a metal can be changed to another form by pulling compression or twisting. For example silver and gold are highly malleable and ductile. It s also highly malleable and with a lower melting temperature of 660 c allowing it to be easily manipulated 6. Ductility and malleability are properties related to deformation of metals. 1 the ductility of steel varies depending on the alloying constituents.

Source: pvcfittingsonline.com

Source: pvcfittingsonline.com

It s also highly malleable and with a lower melting temperature of 660 c allowing it to be easily manipulated 6. Gold silver lead copper aluminium tin platinum zinc iron and nickel. Malleable iron typically has some internal flaws stemming from irregularly shaped carbon particles. The property is not seen in non metals. Sodium potassium and mercury are neither ductile nor malleable however nickel is a nonmalleable metal too.

Source: sorelmetal.com

Source: sorelmetal.com

The most ductile metals are copper aluminum and platinum while the most malleable metals are gold silver and iron. As with iron and aluminium copper is an abundant element on earth with large concentrations found in its crust. Ductility involves tensile stress while malleability involves compressive stress. Lack of ductility is brittleness to understand brittleness lets also take a another mettalic bar this metallic bar when subjected to to axial tensile load we notice that bar does not elongate and fail so brittleness of a material is the property of breaking without much permanent distortion some brittle materials are glass cast iron etc. On the other hand malleability means that a metal.

Source: slideplayer.com

Source: slideplayer.com

However in most cases ductility and malleability are coexisting. Ductility and malleability are properties related to deformation of metals. Malleability denotes the ability to undergo compressive stress. After doing the research and reading the facts we have concluded that while malleable iron is capable of great things ductile iron is the superior alloy. But in some cases ductility is high while malleability is low or vice versa.

Source: metallurgyfordummies.com

Source: metallurgyfordummies.com

Malleable iron typically has some internal flaws stemming from irregularly shaped carbon particles. 1 the ductility of steel varies depending on the alloying constituents. Malleability definition malleability is the ability of a metal to be hammered into thin sheets. On the other hand malleability means that a metal. Ductility and malleability are properties related to deformation of metals.

Source: mytutorialworld.com

Source: mytutorialworld.com

This is the main difference between ductility and malleability. 1 the ductility of steel varies depending on the alloying constituents. Ductility is the ability of a metal to undergo tensile stress. However in most cases ductility and malleability are coexisting. Malleability definition malleability is the ability of a metal to be hammered into thin sheets.

Source: nbenpu.en.made-in-china.com

Source: nbenpu.en.made-in-china.com

Ductility is the ability of a metal to undergo tensile stress. But in some cases ductility is high while malleability is low or vice versa. 1 the ductility of steel varies depending on the alloying constituents. Ductility and malleability are properties related to deformation of metals. Example are gold and silver which are highly malleable.

Source: irondoorsarizona.com

Source: irondoorsarizona.com

For example silver and gold are highly malleable and ductile. On the other hand malleability means that a metal. Gold silver lead copper aluminium tin platinum zinc iron and nickel. For example lead and cast iron are highly malleable though they have a lower ductility. Sodium potassium and mercury are neither ductile nor malleable however nickel is a nonmalleable metal too.

Source: iron-foundry.com

Source: iron-foundry.com

Ductility is the ability of a metal to undergo tensile stress. 1 the ductility of steel varies depending on the alloying constituents. Aluminium is an incredibly ductile material able to be stretched between 50 to 70 of its length before breaking. Ductility is the ability of a metal to undergo tensile stress. This is the main difference between ductility and malleability.

Source: materials-today.com

Source: materials-today.com

After doing the research and reading the facts we have concluded that while malleable iron is capable of great things ductile iron is the superior alloy. When a piece of hot iron is hammered it takes the shape of a sheet. After doing the research and reading the facts we have concluded that while malleable iron is capable of great things ductile iron is the superior alloy. Lack of ductility is brittleness to understand brittleness lets also take a another mettalic bar this metallic bar when subjected to to axial tensile load we notice that bar does not elongate and fail so brittleness of a material is the property of breaking without much permanent distortion some brittle materials are glass cast iron etc. Example are gold and silver which are highly malleable.

Source: pvcfittingsonline.com

Source: pvcfittingsonline.com

Gold silver lead copper aluminium tin platinum zinc iron and nickel. Malleable iron typically has some internal flaws stemming from irregularly shaped carbon particles. Increasing levels of carbon decreases ductility. Lack of ductility is brittleness to understand brittleness lets also take a another mettalic bar this metallic bar when subjected to to axial tensile load we notice that bar does not elongate and fail so brittleness of a material is the property of breaking without much permanent distortion some brittle materials are glass cast iron etc. On the other hand malleability means that a metal.

If you find this site value, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title iron malleability and ductility by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.