Metals that resist corrosion

Metals That Resist Corrosion. Common alloying elements used to increase the corrosion resistance of metals include titanium chromium nickel and molybdenum. Bronze is a copper alloy that includes a large amount of tin and smaller amounts of other alloying elements. Brass is an alloy of copper zinc and other elements which also resists corrosion. The process is called self passivation and it occurs as the metal oxidizes.

Corrosion resistance is an essential factor to consider when selecting metals. Stainless steel for example contains at least 10 5 of chromium. Anodizing aluminum is a process that. Corrosion resistant metals carbon steel. A kind of miracle metal aluminum has the power to create its own corrosion resistant coating. Carbon steels are restricted in alloy content by their composition typically less than 2 percent by weight for complete adds.

Corrosion resistance is an essential factor to consider when selecting metals.

Bronze is a copper alloy that includes a large amount of tin and smaller amounts of other alloying elements. A kind of miracle metal aluminum has the power to create its own corrosion resistant coating. Corrosion resistance is an essential factor to consider when selecting metals. Stainless steel for example contains at least 10 5 of chromium. These metals contain little to no iron which is what prevents them from rusting. Because of their relatively low resistance to corrosion.

Source: azom.com

Source: azom.com

Copper brass and bronze are also corrosion resistant metals. This green layer actually enhances the metals ability to resist corrosion and add to its long life span. Hastens the formation of the resistant coating. Similar to aluminum copper forms a protective oxide layer when exposed to oxygen. Carbon steel the most commonly utilized metal in industry provides for about 85 percent of the world s total steel supply.

Source: industrialmetalsupply.com

Source: industrialmetalsupply.com

This green layer actually enhances the metals ability to resist corrosion and add to its long life span. Because of their relatively low resistance to corrosion. These metals contain little to no iron which is what prevents them from rusting. The process is called self passivation and it occurs as the metal oxidizes. Brass is an alloy of copper zinc and other elements which also resists corrosion.

Source: 911metallurgist.com

Source: 911metallurgist.com

Copper oxidizes over time to form a green patina which actually protects the metal from further corrosion. This green layer actually enhances the metals ability to resist corrosion and add to its long life span. Copper oxidizes over time to form a green patina which actually protects the metal from further corrosion. Similar to aluminum copper forms a protective oxide layer when exposed to oxygen. Bronze is a mixture of copper and tin along with small amounts of other elements and is naturally much more resistant to corrosion than copper.

Source: corrosionclinic.com

Source: corrosionclinic.com

Some metals like cadmium magnesium and zinc have naturally slow kinetics even if their metal surface is thermodynamically favourable to corrosion. Some metals like cadmium magnesium and zinc have naturally slow kinetics even if their metal surface is thermodynamically favourable to corrosion. Copper brass and bronze are all considered red metals. Corrosion resistance is an essential factor to consider when selecting metals. Carbon steel the most commonly utilized metal in industry provides for about 85 percent of the world s total steel supply.

Source: tampasteel.com

Source: tampasteel.com

Copper brass and bronze are also corrosion resistant metals. However red metals do oxidize and can turn green when exposed to oxygen. Acceptable combinations of more or less aggressive fluids and commonly used materials are indicated below. Brass is an alloy of copper zinc and other elements which also resists corrosion. Some metals like cadmium magnesium and zinc have naturally slow kinetics even if their metal surface is thermodynamically favourable to corrosion.

Source: slideshare.net

Source: slideshare.net

However red metals do oxidize and can turn green when exposed to oxygen. Because of their relatively low resistance to corrosion. Stainless steel for example contains at least 10 5 of chromium. Brass is a copper alloy containing a large amount of zinc. The metals most resistant to corrosion are those that are thermodynamically unfavourable to corrosion.

Source: azom.com

Source: azom.com

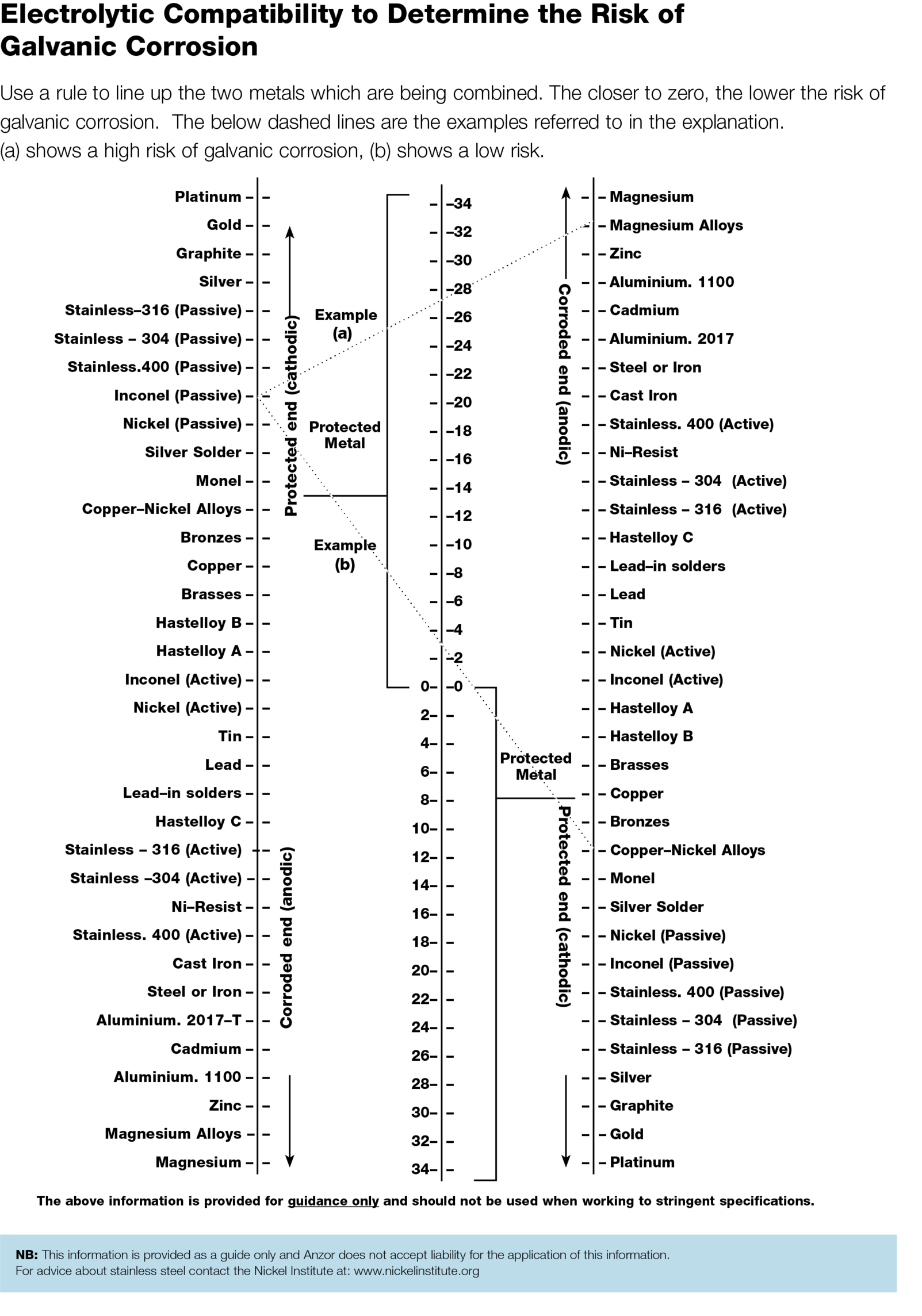

These metals contain little to no iron which is what prevents them from rusting. The metals most resistant to corrosion are those that are thermodynamically unfavourable to corrosion. Bronze is a copper alloy that includes a large amount of tin and smaller amounts of other alloying elements. Corrosion resistance is an essential factor to consider when selecting metals. A major problem in process industry is corrosion of metals in pipes valves and other parts of the constructions.

Source: anzor.com.au

Source: anzor.com.au

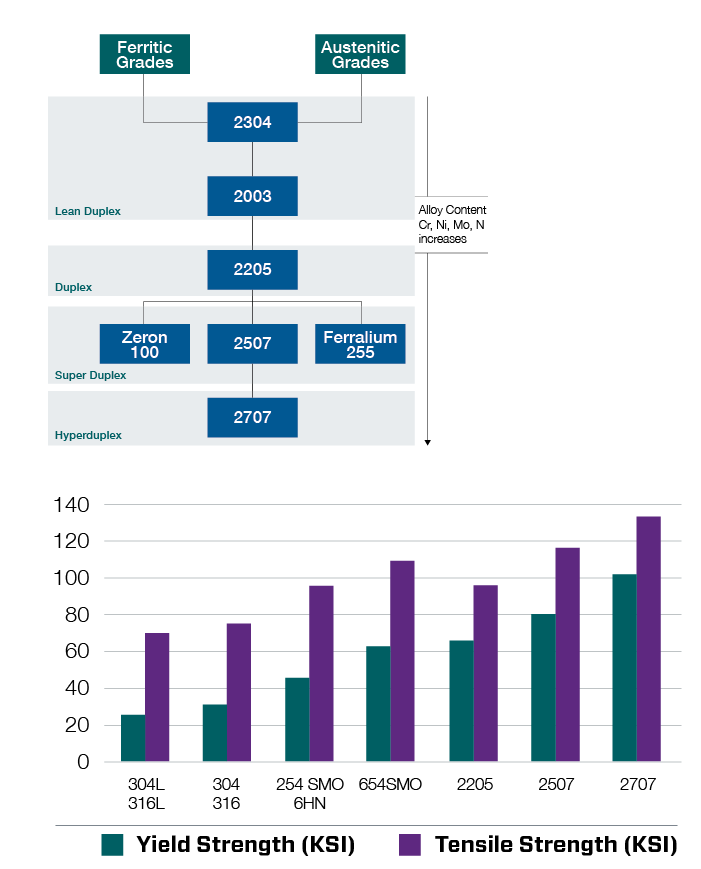

Carbon steel the most commonly utilized metal in industry provides for about 85 percent of the world s total steel supply. Stainless steel for example contains at least 10 5 of chromium. This addition of chromium allows stainless steel to generate a thin and stable chromium oxide layer which limits the intrusion of water and oxygen thus preventing further corrosion. The process is called self passivation and it occurs as the metal oxidizes. This green layer actually enhances the metals ability to resist corrosion and add to its long life span.

Brass is a copper alloy containing a large amount of zinc. Hastens the formation of the resistant coating. These metals contain little to no iron which is what prevents them from rusting. Copper oxidizes over time to form a green patina which actually protects the metal from further corrosion. Some metals like cadmium magnesium and zinc have naturally slow kinetics even if their metal surface is thermodynamically favourable to corrosion.

Source: pumpsandsystems.com

Source: pumpsandsystems.com

The process is called self passivation and it occurs as the metal oxidizes. Corrosion resistance is an essential factor to consider when selecting metals. Bronze is a mixture of copper and tin along with small amounts of other elements and is naturally much more resistant to corrosion than copper. However red metals do oxidize and can turn green when exposed to oxygen. Common alloying elements used to increase the corrosion resistance of metals include titanium chromium nickel and molybdenum.

Source: uneedabolt.com

Source: uneedabolt.com

Similar to aluminum copper forms a protective oxide layer when exposed to oxygen. Corrosion resistant metals carbon steel. However red metals do oxidize and can turn green when exposed to oxygen. This green layer actually enhances the metals ability to resist corrosion and add to its long life span. A kind of miracle metal aluminum has the power to create its own corrosion resistant coating.

Some metals like cadmium magnesium and zinc have naturally slow kinetics even if their metal surface is thermodynamically favourable to corrosion. Carbon steels are restricted in alloy content by their composition typically less than 2 percent by weight for complete adds. The metals most resistant to corrosion are those that are thermodynamically unfavourable to corrosion. Acceptable combinations of more or less aggressive fluids and commonly used materials are indicated below. Brass is an alloy of copper zinc and other elements which also resists corrosion.

Source: waverleybrownall.co.uk

Source: waverleybrownall.co.uk

Stainless steel for example contains at least 10 5 of chromium. A kind of miracle metal aluminum has the power to create its own corrosion resistant coating. Brass is an alloy of copper zinc and other elements which also resists corrosion. Because of their relatively low resistance to corrosion. So where carbon steel forms rusts and crumbles aluminum shines on.

Source: slideserve.com

Source: slideserve.com

Carbon steels are restricted in alloy content by their composition typically less than 2 percent by weight for complete adds. Brass is an alloy of copper zinc and other elements which also resists corrosion. A major problem in process industry is corrosion of metals in pipes valves and other parts of the constructions. This green layer actually enhances the metals ability to resist corrosion and add to its long life span. Acceptable combinations of more or less aggressive fluids and commonly used materials are indicated below.

Source: waverleybrownall.co.uk

Source: waverleybrownall.co.uk

Copper oxidizes over time to form a green patina which actually protects the metal from further corrosion. Brass is an alloy of copper zinc and other elements which also resists corrosion. Carbon steels are restricted in alloy content by their composition typically less than 2 percent by weight for complete adds. Stainless steel for example contains at least 10 5 of chromium. Carbon steel the most commonly utilized metal in industry provides for about 85 percent of the world s total steel supply.

If you find this site helpful, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title metals that resist corrosion by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.